Researchers at DTU Energy Conversion have revamped an HP inkjet printer to cheaply print a fuel cell in 3D with better quality than most other methods. In the near future 3D printing (additive manufacturing) may be used for rapid prototyping of new types of fuel cells along with production of commercial quality fuel cells.

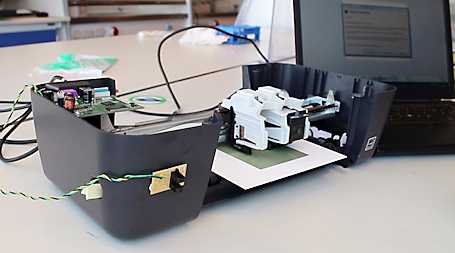

According to DTU, “Research on 3D-printing has been going on for some time, but recently a research team at DTU Energy Conversion … succeeded in modifying an ordinary HP 1000 ink jet printer, costing approx. 400 DKK, enabling it to print inexpensive fuel cells showing superior performances compared to fuel cells fabricated by traditional tape casting.

“Inkjet printing has a tendency to miss a pixel once in a while, resulting in leaks in the electrolyte and a decreased performance, but this problem was solved by printing several layers on top of each other, greatly improving the cell efficiency and still keeping the overall thickness below 10 µm.”

The 3D printer developed by DTU foreshadows the future of hydrogen cars and infrastructure. Many replacement parts along with original parts may one day be manufactured using the 3D printing process.

If you think that this concept is far-fetched then check out the Urbee 2, a car that has been almost entirely manufactured using 3D printing technology. As hydrogen car technology meets 3D printing, the future of both industries looks pretty bright.