Two researchers from the University of Delaware, Erik Koepf and Michael Giuliano spent a couple of months in Switzerland working on a novel sunlight-driven water-splitting device. The initial tests proved that solar fuel (aka hydrogen) could be produced using sunlight, mirrors (no smoke), a reactant and water.

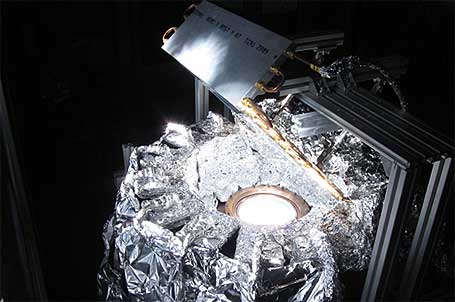

According to the University of Delaware, “Koepf’s reactor is designed to accomplish the first step in a two-step water-splitting process to generate hydrogen renewably from sunlight. The reactor, which is closed to the atmosphere, uses gravity to feed zinc oxide powder (the reactant) into the system through hoppers that dispense the powder onto a ceramic surface. There it undergoes a thermochemical reaction upon exposure to highly concentrated sunlight within the reaction cavity, producing solar fuel.”

The initial tests were conducted on a small-scale mirror and system, producing a modest amount of hydrogen, yet proving the system does work. Koepf and Giuliano now want to scale up the solar reactor and produce as much hydrogen as possible. The only problem is that they needed a mirror four times the size of the one currently on hand and none exists. So they had to build one plus scale up the system as well.

Karen B. Roberts of the University of Delaware reports, “The mirror is a perfectly flat, water-cooled aluminum plate with a 98 percent reflective foil surface. About one-inch thick, the mirror measures 45 by 45 inches square and contains 13 holes bored through the one-inch thick plate along one of the mirror’s axes, enabling water to continuously pass through the channels and cool the mirror’s surface when in use.

“To allow for precise adjustments in real time, the mirror is suspended above the reactor by threaded rods connected to a motor and control assembly, and controlled using a joystick. Placed on a 45 degree angle, Koepf explained, it will enable a perfectly reflected, concentrated light cone that is free of distortion to enter the reactor.”

The 10-foot mirror and 3,000 system have already been shipped to Switzerland. And with any luck weeks from now, this Swiss reactor will run like a clock.

Hello there!

Thought you might be interested in this one:

http://www.fuelcelltoday.com/news-events/news-archive/2013/february/toyota-industries-reveals-new-fuel-cell-forklift

Thanks for the link. That is exciting news indeed about Toyota weighing in on the fuel cell forklift marketplace. I’m surprised that a few other car companies aren’t doing the same.

Aluminum takes a lot of energy to refine… but another means of procuring hydrogen is certainly welcome. The silica nano particles idea seems more plausible to me at this point. So far, the bulk production of hydrogen has still been primarily accomplished by steam reforming natural gas. Enough hydrogen is produced if Oil refining slacks off substantially that in the short term at least, supporting fuel cell vehicles should be no problem. There seems to be a lot of technology that hasn’t been commercialized yet and so many choices on the how to procure hydrogen front that ruling out options will likely be a challenge.

Toyota seems to be late off the mark. Hydrogenics in Canada had a demonstration project at GM many years ago that was a great success. They did not need compressed hydrogen to fuel it, either.

http://www.hydrogenics.com/?s=material+handling+fuel+cell

Yep, Toyota is playing catchup right now, which is what they tend to do. Before they introduced the Prius plug-in there was a group of engineers in northern California retrofitting their own Prius plug-ins and begging Toyota to come out with a commercial version. It took years, but finally Toyota saw the light. And because of name recognition, Toyota will have an easier time catching up in the fuel cell forklift market. Better late than never, though.